In commercial baking, the texture of cookies and production efficiency depend on the choice of oven.

Issues like undercooked centers in thin and crispy cookies, burnt surfaces on chocolate chip cookies, and leaking fillings in sandwich cookies mostly stem from mismatched ovens and cookie types.

This article recommends suitable commercial cookie oven models based on the baking needs of 4 common cookie categories: thin and crispy, thick and soft (e.g., cookies), sandwich/multi-layered, etc.

Common Types of Cookies

1. Thin and Crispy Cookies

Characterized by thin thickness (usually ≤3mm), extremely crispy texture, and mostly salty or mild flavor. Common examples include seaweed thin crisps, sesame thin crisps, and potato crisp cookies.

– Basic Flavor Thin Crisps: Such as original thin crisps, sea salt thin crisps, and chive thin crisps, mainly made from wheat flour.

– Ingredient-Added Thin Crisps: Seaweed thin crisps, sesame thin crisps, and potato crisp cookies.

– Functional Thin Crisps: Whole-wheat thin crisps, sugar-free thin crisps, and low-oil thin crisps.

2.Cookie

High in butter content, with a crumbly and dense texture, often containing nuts or chocolate chips. Common examples include chocolate chip cookies, butter cookies, and cranberry cookies.

– Classic Butter Cookies: Original butter cookies, Danish butter cookies.

– Ingredient-Added Cookies: Chocolate chip cookies, cranberry cookies, nut cookies.

– Special Texture Cookies: Soft cookies, crispy cookies, filled cookies.

3. Compressed Cookies

High density, firm texture, and long shelf life. Often used as outdoor emergency food or military rations.

– Outdoor Emergency Type: Regular compressed cookies, flavored compressed cookies.

– Function-Enhanced Type: High-calcium compressed cookies, high-protein compressed cookies, low-sodium compressed cookies.

– Scenario-Specific Type: Military compressed cookies, marine compressed cookies, disaster relief compressed cookies.

4. Specialty Cookies

Including digestive biscuits, meringue cookies, filled wafer rolls, wafer cookies, soda crackers, sandwich cookies, oatmeal cookies, etc.

How to Choose a Commercial Cookie Oven? Recommendations for Ovens Suitable for Different Cookie Production

1. Thin and Crispy Cookies (e.g., Soda Crackers)

Thin and crispy cookies are suitable for rack ovens or tunnel ovens with strong hot air circulation:

– Strong Hot Air Circulation: Enables rapid and even dehydration of cookies, avoiding local burning and achieving a thin, crispy texture.

– High Temperature Control Precision: Requires ±1℃ accurate temperature control to prevent cookie burning due to temperature fluctuations.

Equipment Type Adaptation:

– For small-batch baking: Choose a rack oven, e.g.:

https://www.nicko.com.cn/product/12-16-32-64trays-rotary-oven/

– For large-batch baking: Choose a tunnel oven (supports continuous conveying and high output), e.g.:

2. Thick and Soft Cookies (e.g., Chocolate Chip Cookies)

Thick and soft cookies are suitable for combination ovens with hot air + steam functions. Steam prevents the surface from hardening prematurely, keeping the cookies soft; the oven should have a segmented temperature control function.

You can also choose Nicko’s Rotary Oven series:

– First, the rotating design of this oven ensures even heat distribution to all parts of thick and soft cookies, allowing the interior to be fully cooked without burning the surface, thus achieving the ideal thick and soft texture.

– Moreover, this oven uses advanced electric heating technology and a high-precision temperature control system, which can accurately maintain stable temperature and humidity, avoiding taste issues caused by excessively high or low temperatures.

– In addition, some models of Nicko’s rotary ovens adopt a combined heating method of hot air and infrared, which better retains moisture inside the cookies. The oven’s air outlets also have 3 types of 7-stage adjustment modes, making it easy to adjust the baking effect.

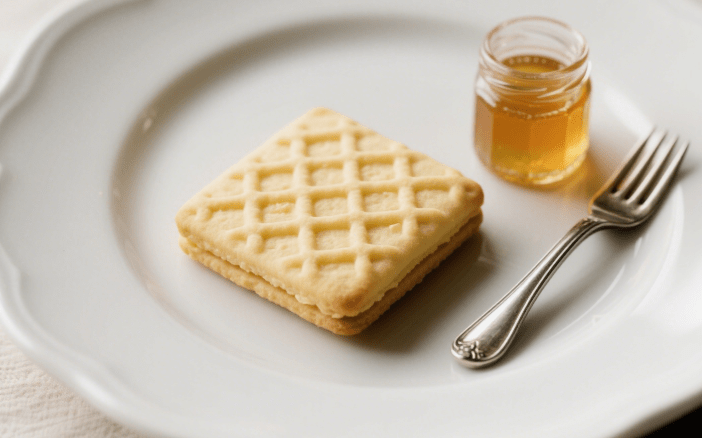

3. Sandwich/Multi-Layered Cookies

The production of sandwich/multi-layered cookies has extremely high requirements for temperature stability:

– First, each layer of dough for multi-layered cookies needs to be fully cooked simultaneously (e.g., multi-layered structures with crispy outer layers and soft inner layers). Uneven temperature in the oven can lead to “burnt outer layers and undercooked inner layers”.

– In addition, fillings such as chocolate, jam, and cream are extremely sensitive to temperature: excessively high temperatures cause fillings to melt and leak, while excessively low temperatures result in poor adhesion between layers.

It is recommended to prioritize industrial tunnel ovens (supports continuous conveying and adapts to mass production), e.g., Nicko’s Industrial Electric Cake Bread Biscuit Tunnel Oven:

https://www.nicko.com.cn/product/nickos-industrial-electric-cake-bread-biscuit-tunnel-oven/

– This oven is equipped with “advanced electric heating technology + precision temperature control system”, which continuously provides a precise and uniform temperature and humidity environment, ensuring simultaneous heat distribution to each layer of dough and maintaining the integrity of the sandwich/multi-layered structure.

– The special structure of sandwich/multi-layered cookies is well-matched by the oven’s multiple working modes (top-bottom heating, top-bottom strong convection, middle strong convection):

– For “multi-layered cookies with crispy outer layers and soft inner layers”: Select the “top-bottom heating + weak convection” mode.

– For “multi-layered cookies with filling in the middle”: Activate the “middle strong convection” mode to allow heat to penetrate the multi-layered dough.

– For “large-area, thin sandwich cookies”: The “top-bottom strong convection” mode enables rapid circulation of hot air, ensuring uniform filling thickness in each cookie.

– In addition, the production process of sandwich/multi-layered cookies is more complex than that of ordinary cookies, requiring steps such as “baking multi-layered dough → cooling → filling application/layering → secondary baking (for some categories)”. This oven supports “automated assembly line operations”: cookie dough can be continuously fed into the oven via a conveyor belt, enabling “uninterrupted mass production” and suitable for large-volume orders.

Key Performance Parameters for Selecting a Commercial Cookie Oven

– Material: Prioritize ovens with 304 stainless steel inner chambers. As the most cost-effective material for ovens on the market, it offers advantages such as high temperature resistance and corrosion resistance.

– Temperature Control: Ovens with segmented temperature control (e.g., independent adjustment of top and bottom heat) are suitable for producing multiple types of cookies.

– Energy Consumption: Choose ovens with thermal insulation layers and intelligent shutdown functions to reduce long-term energy consumption and costs.

– Functions: Prioritize ovens with automatic cleaning and fault alarm functions to reduce maintenance costs.