When a cake cracks at the top due to temperature control deviations, the success or failure of commercial baking often hinges on the precision of the oven.

Commercial ovens for cake baking are far more than mere “heating containers”—they are professional equipment integrating temperature control technology, heat distribution, and production capacity planning. From basic large ovens to those enhanced by cutting-edge technology, modern commercial baking equipment is redefining “quality consistency” through technological innovation.

This article dissects the core competitiveness of professional ovens across five dimensions—temperature control precision, heating methods, capacity design, etc.—to help you select the most suitable oven for cake baking.

Precise Temperature Control: The Cornerstone of Cake Baking

Commercial ovens for high-volume cake production must feature high-precision temperature control systems, and here’s why:

1. Harmonizing Starch Gelatinization and Protein Coagulation

Accurate temperature control ensures that flour starch and egg whites gelatinize simultaneously at 60°C. Inadequate temperature leads to sunken cake interiors, while excessive heat causes dry, cracked textures—both resulting in baking failure.

– Case in point: Chiffon cakes require baking at 150–170°C. A temperature fluctuation exceeding 5°C can cause the top to crack while the inside remains undercooked. Precisely controlled heat also prevents premature oil melting, which could burst air bubbles.

Nicko Oven’s Premium Core Components

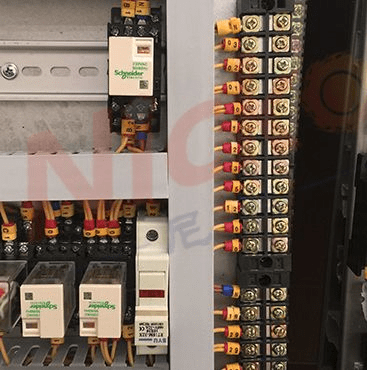

Nicko ovens are equipped with internationally top-tier core components, including:

- Original Schneider relays, renowned for precise electrical control and long-term stable operation.

- Imported Japanese burners, ensuring efficient combustion, uniform heat distribution, and reliable performance.

2. Adapting to Diverse Cake Types

– Sponge cakes need low-temperature slow baking (to reduce water loss), while cheesecakes require high-temperature fast baking (180–200°C to accelerate caramelization). In commercial bakeries handling varied recipes, imprecise temperature control compromises product quality.

3. Preventing Baking Failures

During baking, cakes need rapid initial heating for expansion, followed by constant temperature to set the starch. Slow heating causes collapse, while mid-bake temperature drops create a “pudding layer”. Soufflés, for instance, are extremely temperature-sensitive: baking at 200°C for 12–15 minutes with any deviation risking immediate failure.

Uniform Heating: Techniques and Applications

Common Uniform Heating Technologies

1. Independent Top-Bottom Heating Tubes with Separate Temperature Control

– Ideal for cakes needing colored tops and thoroughly cooked bottoms, such as chiffon and sponge cakes.

2. M-shaped/Multi-group Heating Tubes

– Suited for baking 2–3 trays simultaneously, reducing temperature differences between edges and the center (e.g., 4-group M-shaped tubes in commercial ovens).

3. Hot Air Circulation System (Fan-assisted Heating)

– Perfect for high-moisture cakes (e.g., cheesecakes); some ovens offer a hybrid “top-bottom heat + hot air circulation” mode.

4. Infrared Heating Technology

– Heats 50% faster than traditional tubes, ideal for cakes requiring rapid shaping (e.g., éclair batter).

Scenario-based Recommendations

1. Small bakeries: Choose ovens with independent top-bottom heating tubes + basic hot air circulation.

2. High-end pastry shops: Opt for M-shaped tubes + multi-gear hot air circulation + infrared assistance, suitable for macarons and French mille-feuille. [Nicko professional multi-layer infrared rotary oven](https://www.nicko.com.cn/products/oven/rotary-oven/).

3. Central kitchens: Select tunnel ovens, such as Nicko’s model [here](https://www.nicko.com.cn/products/oven/tunnel-oven/), capable of baking 500–1,000 cake batters per hour.

Large Capacity: Ensuring Consistent Quality

Commercial ovens typically offer multiple layers, measured by 40×60cm standard trays—options include 1-tray, 2-tray, 4-tray, or 6-tray configurations. For example, [this oven](https://www.nicko.com.cn/product/12-16-32-64trays-rotary-oven/) even supports up to 64 trays for mass baking.

1. Productivity Enhancement

– Large-capacity ovens reduce baking batches, ensuring consistent taste and color for high-volume production. Multiple small oven batches often lead to quality inconsistencies noticeable to customers.

2. Energy Efficiency

– Despite higher power, large ovens are more energy-saving. Example: A 1,500W small oven uses 0.75 kWh per tray (30 minutes), while a 3,000W large oven baking 4 trays consumes 1.5 kWh total—only 0.375 kWh per tray.

Durability: Core of Commercial Kitchen Equipment

Premium cost-effective commercial ovens feature stainless steel liners, resisting high temperatures, corrosion, and easy cleaning—essential for heavy-duty use.

Nicko Oven’s Combustion Chamber Protection Design

- Adopts 10-15mm thick fire arrester castings, which effectively prevent combustion chamber burnout, air leakage, and deformation.

- This design extends the service life of the combustion chamber, significantly reducing customers’ follow-up maintenance costs and enhancing equipment durability.

Safety Features: Non-negotiable for Commercial Use

Top commercial ovens include auto-shutoff and overheat protection—features standard in Nicko’s ovens, a leading Chinese brand.

– Nicko’s safety design: Explosion-proof tempered glass doors (withstanding 400°C temperature differences), double-layer heat insulation, and overheat-powered shutdown to prevent fires and scalds.