For bakeries, biscuit factories, and large-scale baking workshops, a high-quality industrial oven for baking is a core piece of equipment that ensures stable mass production and consistent quality.

However, the market is filled with a wide variety of industrial ovens—including tunnel ovens, rotary ovens, and deck ovens. How do you determine which one fits your baking needs and production capacity?

Combining the purchasing experience of over 10 industrial baking enterprises, this article helps you avoid common pitfalls (such as “focusing only on price and ignoring material quality”) and provides specific purchasing recommendations for industrial ovens for baking from multiple dimensions, ensuring you select an industrial baking oven that can support long-term production.

I. Determine Oven Requirements Based on Industrial Baking Scenarios and Production Capacity

1. How to Choose an Oven by Baking Category?

For example, choose ovens with steam function for bread/cake baking. Among these, an adjustable steam function is crucial: in the first 10 minutes of baking, steam prevents the bread crust from hardening too early, allowing the dough to form larger, airy pores. Additionally, bread baking requires gradient temperature control (with high precision) and uniform heating.

Suitable Oven Types: Industrial deck ovens and rotary ovens equipped with independent steam generators.

2. How to Determine Oven Specifications by Production Capacity?

In simple terms:

– For small-batch baking: Choose deck ovens, such as Nicko’s deck oven series:

https://www.nicko.com.cn/products/oven/deck-oven/

– For large-batch baking: Choose tunnel ovens or rotary ovens, such as Nicko’s rotary oven series:

https://www.nicko.com.cn/products/oven/rotary-oven/

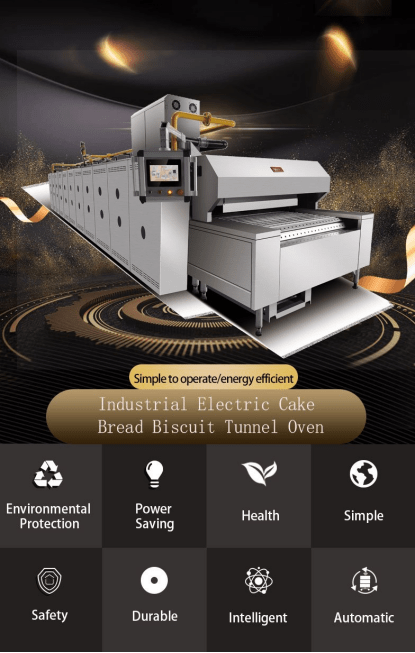

And Nicko’s tunnel oven series:

https://www.nicko.com.cn/products/oven/tunnel-oven/

Reference for Matching Oven Types by Production Scale

| Production Scale | Daily Output Range | Suitable Oven Types | Core Advantages | Application Scenarios |

| Small-batch | 50-300 servings (e.g., biscuits, small cakes) | Desktop deck ovens (2-4 trays), small rotary ovens (6-12 trays) | Small footprint, flexible operation | Private baking studios, small bakeries, restaurant kitchens |

| Medium-batch | 300-1000 servings (e.g., toast, cookies) | Vertical deck ovens (6-12 trays), medium rotary ovens (16-32 trays) | High single-batch capacity, supports multi-category switching | Chain bakery stores, medium-sized food factories (multi-category production) |

| Large-batch | Over 1000 servings (e.g., industrial biscuits, bread) | Tunnel ovens (continuous conveying), large rotary ovens (64+ trays) | Uninterrupted continuous production | Large food processing plants, central kitchens (single-category mass production) |

II. Key Parameters to Consider When Purchasing an Industrial Oven for Baking

1. For the same production capacity, prioritize equipment with shorter baking time and faster cooling. For example, when baking toast, a standard deck oven takes 30 minutes per batch, while a deck oven with hot air only takes 25 minutes per batch—allowing 2-3 more batches to be baked daily.

2. For large-batch production, choose tunnel ovens with automatic conveying or rotary ovens with automatic temperature control to reduce labor costs; for small-batch production, opt for “manual adjustment” equipment to lower costs.

3. The best temperature control precision is ±1-3℃, which ensures consistent quality and taste for each batch of baked goods.

4. Prioritize ovens with hot air circulation and multi-heating tube layout. Such ovens provide uniform heating, maintaining relatively consistent temperatures across all areas inside the oven and preventing local burning or undercooking.

5. In terms of material, it is recommended to purchase ovens with 304 stainless steel inner chambers. These ovens are more heat-resistant, easier to clean, and compliant with food safety standards—making them particularly suitable for industrial baking scenarios. Additionally, stainless steel ovens are more durable and reliable, often boasting a longer service life.

6. Auxiliary functions of some ovens are also important. Features such as fault alarms and intelligent temperature control not only enhance the safety of industrial production but also reduce long-term operating costs.

7. The safety design of baking equipment is equally critical. Functions like overheating protection and leakage protection are essential for high-frequency use in industrial baking scenarios.